E-beam lithography is the process of using the concentrated electron beam to create models having the change, deposition, and removal of material on the surface of particles. The additives and subtractors on the substances allow the deep scanning of the substance with the usage of an electron beam.

Electron Beam Lithography: All We Need To Know

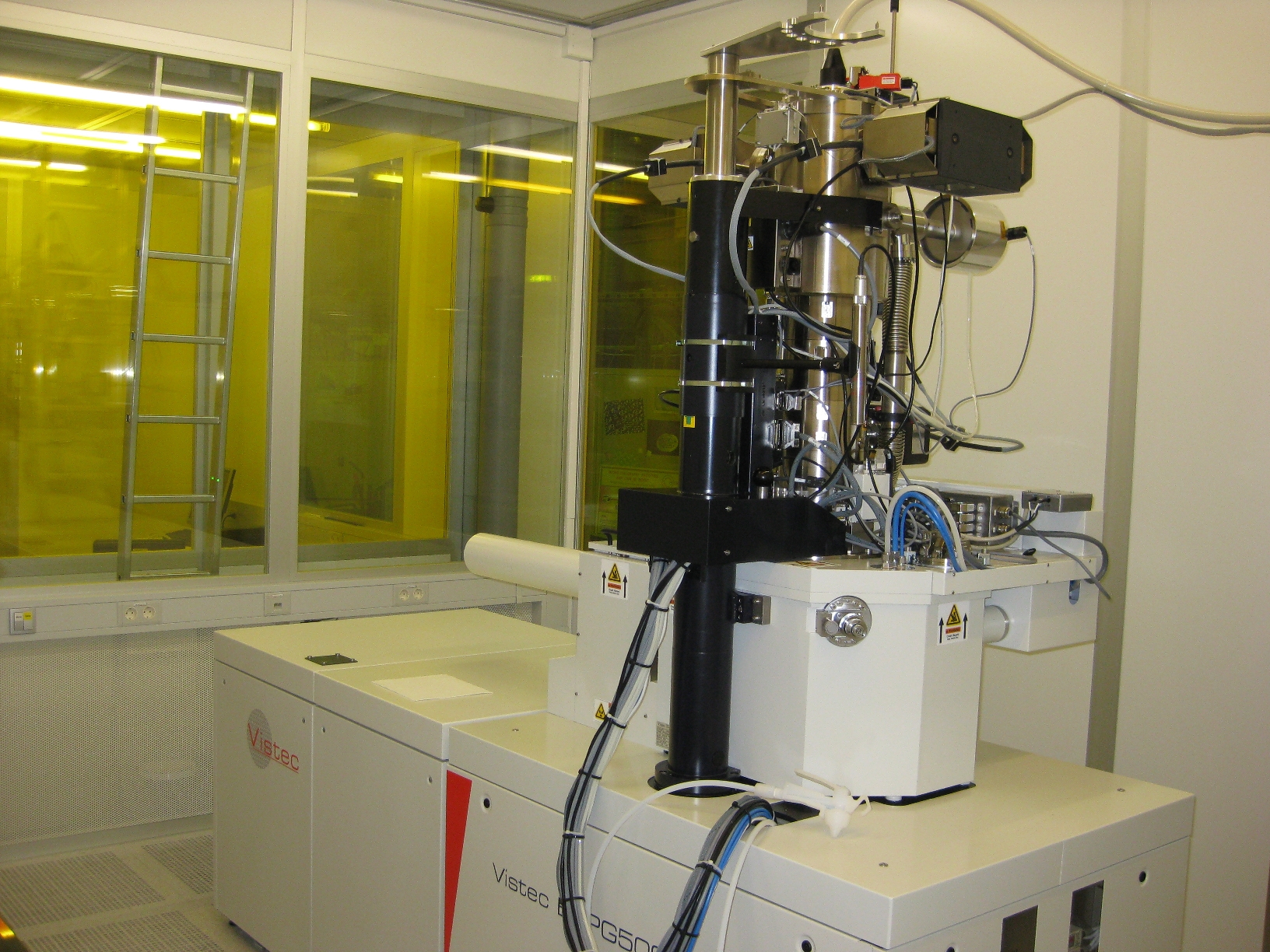

This is a basic manufacturing process in the semiconductor industry that uses the electron beam to create specific patterns on the material surface having resistance. Lithography is also popular for having a high resolution, simplicity, and no masking needs.

The materials whose surfaces are covered with even a few nanometers of electrons can be analyzed with the E-beam lithography. The electron particles can be very tiny but helpful in creating specific patterns. The entire material surface area can be chosen with the process. Some portions can also be exposed or covered with the electron beam as per the requirement.

The lithography even allows covering the exposed portions while offering protection to the covered parts on the surface. It has a shorter wavelength of electrons that leads to the high speed of the electron beam and maximized results. Photolithography comes with a larger wavelength and hence is avoided for in-depth scanning or analysis of the particles.

The process does miss a diffraction limit on the lowest dimension due to the short wavelength of the electron. However, their high energy keeps up the pace of the beam. It seems to have a sort of impact of forwarding and back-scattering from the resistance.

- The lithography companies make the best use of the focused electron beam to write the patterns on the nanoscale. This method is highly preferred with a resist substance whose solubility changes when exposed to electron beam radiation. The electron beam lithography produces a high resolution of patterns as the wavelength is less than 0.01nm.

The in-depth resolution of e-beam lithography can be found by distributing the primary and secondary electrons on the resistance substrate. It is a serial process and not mass production. The ion beam lithography and laser lithography are mass production solutions.

- E-beam lithography is capable of narrowing down the higher pattern resolution as compared with the traditional methods. It is majorly used in the creation of photomasks and mask-free lithography. The electron beam scans the coated surface of the substrate that generates the final pattern from the digital representation. Laser lithography is also possible, but it is usually slower than photolithography.

- The lithography companies are also reliable solutions to surface patterning. It is based on focused light, and a concentrated electron beam is used to create the patterns. The wavelength of the beam is shorter, and hence the acceleration is higher. This even generates the possibility of cross-linking while the electron beam is concentrated. The resolution is higher than photolithography. It can create patterns on the nanoscale. The affordable costs of this technique make it a more suitable EBL option for creating specific patterns on the surface of materials. The process to form patterns by e-beam radiation is used to bind the biomolecules in specific designs that can be considered as the prominent example of EBL.

- The EBL process is highly effective for nanostructured materials. The process can go up to the lower limits for both clusters and distances. In photolithography, the limit is a bit higher and hence not preferred. E-beam lithography companies are in higher demand as compared with many others.

- Lithography plays a key role in the process of micro miniaturization. The optical specifications of these devices can be investigated with care. Since the electron beam should be deflected away from the optical axis, the detrimental effects are easy to capture.

- Electron beam lithography plays a vital role in the micro-structuring of the substance. The electron beam is focused from a distance of fewer than 10 nanometers, forming a precise photo with limited detailing. This method is highly preferred in fabricating masks. The process can be time-consuming but highly efficient due to its great resolution.

- The e-beam lithography is combined with both wet and dry itching to create the planar mediums. These are available from low visibility wavelengths to infrared wavelengths. There is a lot of other integration and additional possibilities with electron beam lithography.

The majority of the electron beam lithography process and mechanism requires heavy working and systems. The single-beam technique is not effective as compared with the available optical devices. The e-beam lithography is not used in high-volume production and is preferably used for masking. Hence it can be used to improve the output by reducing the equipment size involved during the entire process. We hope that the above-shared details prove valuable to every reader out there.